Reachable at 9560662883  011-46039993 (Ext. 21 to 32) (10am - 06pm)

011-46039993 (Ext. 21 to 32) (10am - 06pm)

You have no items in your shopping cart.

Contact Your Vendor

Authorised Distributor/ Stockist/ Importer

VFD PANELS 440 V

VFD (Variable Frequency Drive) Panels 440V are electrical control panels used to regulate the speed and torque of electric motors by controlling the frequency and voltage of the power supplied to the motor. The VFD Panel 440V is designed to operate with a voltage range of 440V and can handle a wide range of electrical loads, including motors, pumps, fans, and other equipment.

HEATING CONTROL PANEL

The Heating Control Panel is an advanced control system designed to regulate and manage heating systems for residential, commercial, and industrial applications. This device provides an efficient and convenient solution for maintaining a comfortable temperature in buildings of all sizes.

The control panel features an intuitive user interface that allows for easy programming and operation. It can be configured to control multiple zones, each with its own temperature settings and timing schedules. The temperature can be adjusted using a digital thermostat, and the system can also be remotely controlled via a mobile app.

The Heating Control Panel is equipped with a range of safety features, including over-temperature protection, short-circuit protection, and power surge protection. It is also designed to be energy-efficient, with features such as automatic shut-off and intelligent temperature sensing that helps to reduce energy consumption.

AC Drive Input Phase Three Phase

An AC Drive Input Phase Three Phase is an electronic device used to regulate the speed of AC motors in various industrial applications. The device is designed to convert the incoming power supply, typically from the electrical grid, to the required voltage and frequency needed to drive the motor.

With its advanced control algorithms and power electronics, the AC Drive Input Phase Three Phase allows for precise and efficient control of motor speed and torque. This can lead to significant energy savings, improved process control, and reduced wear and tear on the motor and associated equipment.

The AC Drive Input Phase Three Phase is typically used in a wide range of industrial applications, including pumps, fans, conveyors, and other types of machinery. It is also commonly used in HVAC systems, where it can help to optimize energy consumption and improve comfort levels.

Overall, the AC Drive Input Phase Three Phase is a reliable and effective solution for controlling the speed and torque of three-phase electric motors, making it an essential component in many modern industrial and commercial settings.

APFC PANEL 415 V

An Automatic Power Factor Correction (APFC) Panel 415V is an electrical control panel designed to optimize the power factor of a three-phase electrical system. The panel works by measuring the power factor of the load and automatically adjusting the capacitance of the power factor correction capacitors to maintain a power factor close to unity (1).

The APFC Panel 415V is typically installed in industrial and commercial buildings where there are large inductive loads such as motors, transformers, and other heavy machinery. By correcting the power factor, the panel ensures that the electrical system operates at maximum efficiency, which results in significant energy savings and reduced power bills.

The panel is constructed with high-quality materials and components to ensure durability and reliability. It is designed to provide accurate and stable power factor correction in all operating conditions. The APFC Panel 415V is also equipped with safety features such as overload protection, short circuit protection, and over-temperature protection to prevent damage to the panel and the electrical system.

The APFC Panel 415V is easy to install and operate, and it comes in various sizes and configurations to meet the specific power factor correction requirements of different applications. It is also easy to maintain, and its modular design allows for easy replacement of faulty components.

Old AC Drive

An Old AC Drive is an electronic device used to regulate the speed of AC motors in various industrial applications. The device is designed to convert the incoming power supply, typically from the electrical grid, to the required voltage and frequency needed to drive the motor.

CONTROL PANEL BOARD 230-415V

A Control Panel Board 230-415V is an electrical distribution panel used to distribute and control power in various industrial applications. The device is designed to receive incoming power from a transformer or electrical grid and distribute it to various loads and equipment in the facility.

HAVELLS DRIVE PANEL

The Havells Drive Panel is a high-performance motor control panel that is designed to offer superior functionality and efficiency in industrial settings. This advanced panel is engineered to control and protect electric motors in a wide range of industrial applications.

The panel is constructed with high-quality materials and features an advanced microprocessor-based control system. This system offers precise control of motor speed, torque, and position, making it suitable for demanding industrial applications that require high levels of accuracy and reliability.

The Havells Drive Panel is also designed to offer enhanced safety features to protect both the motor and the operator. It features an overload protection system that shuts down the motor in the event of an overload or short circuit. This feature helps to prevent damage to the motor and other connected equipment and also ensures that the operator remains safe during operation.

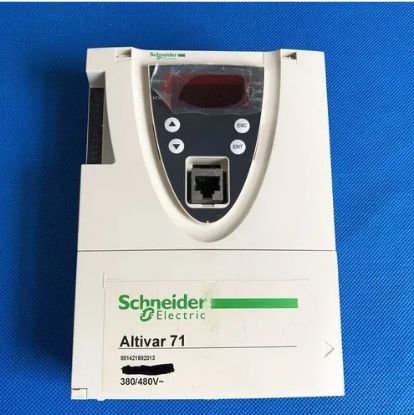

Schneider Atv 71 power Cards

Schneider ATV 71 Power Cards are electronic components that are designed to be used with Schneider Electric's ATV 71 series of variable frequency drives. The power cards are an essential component of the drive system, providing the necessary power electronics to convert the incoming AC power into the precise voltage and frequency required to operate the motor.

Schneider Atv71control Card

The Schneider ATV71 control card is a compact and robust electronic device that is designed to fit seamlessly into the Altivar 71 series of VFDs. The control card provides advanced control and monitoring capabilities that enable precise control of motor speed and torque, as well as real-time monitoring of various parameters such as current, voltage, and temperature.

Parker Ac Drive Input Phase 3 - Phase

The Parker AC Drive Input Phase 3-Phase is an electronic component designed to be used with Parker AC Drives. The input phase refers to the electrical power supplied to the drive system. The Parker AC Drive Input Phase 3-Phase is designed to be used with three-phase electrical power sources, which are commonly used in industrial applications.

Schneider Vfd Motor Power 0.75 to 260kw

The Schneider VFD is a variable frequency drive designed for precise control of industrial motors. With a motor power range of 0.75 to 260 kW, this VFD is highly versatile and can be used in a variety of industrial applications. It features advanced technology that allows for precise control of motor speed and torque, ensuring maximum efficiency and performance.

The Schneider VFD is easy to install and use, with a user-friendly interface and controls. It is also designed with safety features, such as overload protection, to protect both the motor and the operator during operation. The VFD is highly energy-efficient, helping to reduce energy consumption and operating costs.

Overall, the Schneider VFD is a reliable and efficient choice for businesses looking to optimize the performance of their industrial motors. Its advanced technology and versatility make it an ideal choice for a wide range of applications, and its energy efficiency and safety features make it a smart investment for any business.

Schneider Electric Plc Pulse Transmission Output single to three

The Schneider Electric Plc Pulse Transmission Output Single to Three is a highly efficient and reliable component designed to be used with Programmable Logic Controllers (PLCs) in industrial applications. It is designed to convert single pulse inputs to three isolated outputs, making it an essential tool for any industrial automation system.

The output module is designed to offer highly accurate pulse output, with a maximum output frequency of 100 Hz. This high frequency and accuracy makes it perfect for a wide range of applications, including manufacturing, processing, and packaging industries.

The module is incredibly easy to install and set up, with clear and concise instructions provided. It features a compact design, making it easy to fit into any control panel or enclosure. Additionally, the module is highly durable, designed to withstand harsh industrial environments and operating conditions, making it ideal for use in rugged applications.

Overall, the Schneider Electric Plc Pulse Transmission Output Single to Three is an exceptional component that offers reliable, high-performance pulse output for industrial automation systems. Its compact design, easy installation, and durability make it a smart choice for any industrial application.

PLC Schneider PLC Brand TM241

The Schneider PLC Brand TM241 is a versatile and high-performance Programmable Logic Controller (PLC) designed for use in industrial automation applications. It is a powerful and reliable device that can help you optimize your manufacturing processes and improve efficiency.

The TM241 PLC is part of the Modicon M200 range, which is renowned for its superior performance and durability. It features a compact and robust design, making it easy to install and maintain, and it is suitable for use in a wide range of environments, from small standalone machines to complex systems.

With its advanced features, the TM241 PLC can help you streamline your operations and achieve better results. It features an intuitive user interface and can be programmed using a variety of programming languages, including ladder logic, function block diagram, structured text, and instruction list.

The TM241 PLC is also equipped with a range of communication ports, making it easy to connect to other devices and integrate into existing systems. Additionally, it features built-in web and FTP servers, enabling you to remotely monitor and manage your operations from anywhere.

Overall, the Schneider PLC Brand TM241 is a high-performance and reliable device that can help you streamline your operations, improve efficiency, and reduce costs. Its compact design, advanced features, and ease of use make it an ideal solution for a wide range of industrial automation applications.

Schneider Electric Plc Manufacturer Series TM200, TM241, TM221

Schneider Electric offers a range of high-performance Programmable Logic Controllers (PLCs) under the TM200, TM241, and TM221 series, designed for use in a variety of industrial applications. These PLCs are designed to offer the latest in technological innovation, ease of use, and reliability.

The TM200 series of PLCs is designed for use in small-scale automation applications, with an emphasis on cost-effectiveness and ease of use. It is a compact and reliable device that is ideal for standalone machines and simple systems.

The TM241 series of PLCs is ideal for mid-range automation applications, with advanced features such as built-in Ethernet and a web server, making it easier to remotely access and manage your systems. It is also equipped with an advanced set of programming tools, making it easier to create customized automation programs.

The TM221 series of PLCs is designed for use in demanding automation applications, with a focus on high-performance and reliability. It is equipped with advanced features such as CANopen and Modbus communication protocols, enabling it to connect to a wide range of devices and systems. It is also designed to operate in harsh environments, making it ideal for use in challenging industrial settings.